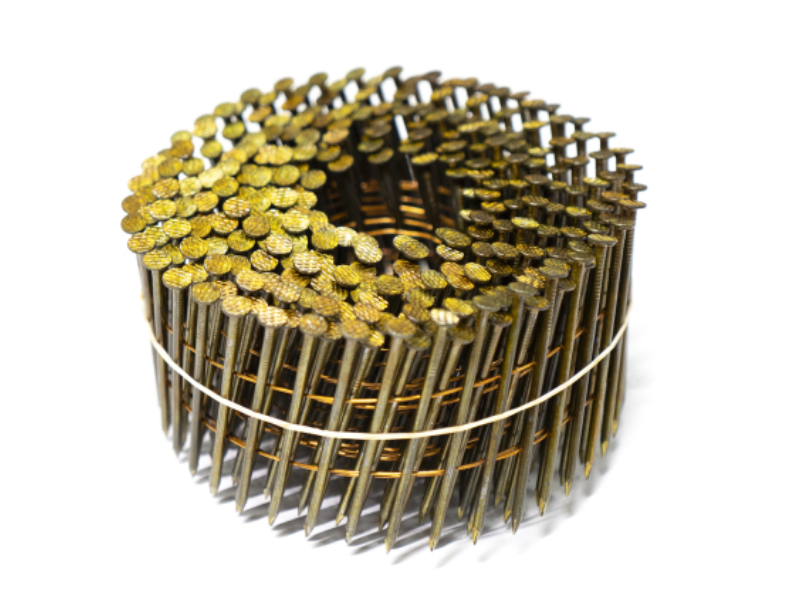

Coil Nails Detailed Introduction

Coil nails are designed with a nail body angle (β) ranging from 0 to 90 degrees. Cixing Metal Coil Nails are compatible with nail machines, enabling continuous nailing, which significantly reduces manual labor and increases productivity. These nails have a wide range of applications, making them particularly suitable for industries such as construction, decoration, furniture, woodworking, packaging, and automotive.

Applications of Coil Nails:

Coil nails are ideal for use in soft and hard wood, bamboo products, ordinary plastics, clay walls, furniture repair, and wooden packaging boxes. They are widely used in construction, decoration, and renovation projects.

Nail Rod Treatments:

The nail rod treatments include thread, ring, and smooth rods. Smooth rods are easy to remove, while threaded rods are used for securing hardwood connections, and ring nails are suitable for connecting softwood. Coil nails can be treated with various surface finishes, such as lacquer dipping, galvanizing, color zinc plating, and Dacromet coating. Domestically, lacquer dipping is the most commonly used method. The uniformity of lacquer dipping plays a significant role in lubrication, fastening, and rust prevention.

Nail Head Types:

Coil nails come in different head types, including pointed, blunt, chisel point, and blunt chisel. The choice of head type depends on the hardness and toughness of the material being worked with. There is a common misconception that the sharper the nail, the better it performs. However, each nail type has a specific application, and the selection should be based on the particular task at hand. The compatibility of the nail gun and coil nails is also essential. When choosing nails, it is important to ensure that they are compatible with the nail gun being used.

Welding Wire:

The quality of the welding wire used in coil nails is crucial. High-quality welding wire has the perfect balance of hardness and toughness, with neat weld points. Inferior welding wire is prone to deformation and breakage during use, which can cause nail jams. Therefore, the choice of welding wire plays a vital role in the overall performance and reliability of coil nails.